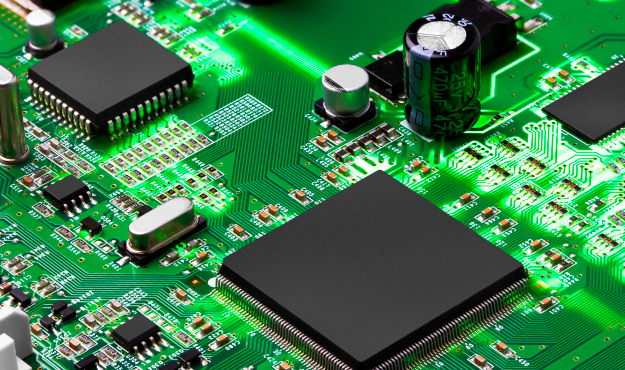

The Evolution of PCBs: Pioneering the Electronics Revolution

Printed Circuit Boards (PCBs) have been instrumental in revolutionizing the electronics industry since their inception. These vital components have undergone significant evolution, shaping the way electronic devices are designed, manufactured, and utilized across various domains. In this article, we'll explore the journey of PCBs, from their humble beginnings to their modern-day applications. Check out blind micron to learn more.

A Brief History

Origins of PCBs

The concept of PCBs can be traced back to the early 20th century when engineers sought ways to simplify and enhance electronic connections. The first PCB-like structures were developed using thin wooden boards or even Masonite, with metal wires glued onto the surface to create rudimentary circuitry.

World War II Advancements

PCBs gained prominence during World War II when the need for reliable electronic equipment spurred innovation. The United States military played a pivotal role in advancing PCB technology, using them in radar systems and military communication devices. This era saw the emergence of the "printed" circuit board, where conductive tracks were etched onto copper-clad boards, a significant leap from manually wiring components.

PCB Evolution

Transition to Silicon

With the dawn of the semiconductor age in the 1950s and 1960s, the need for more compact and efficient PCBs grew. Silicon chips and integrated circuits (ICs) started replacing discrete components, allowing for greater miniaturization. PCBs adapted to accommodate these new technologies, featuring smaller components and intricate circuitry.

Surface Mount Technology (SMT)

In the 1980s, Surface Mount Technology (SMT) revolutionized PCB assembly. SMT components, smaller and lighter than their through-hole counterparts, allowed for higher component densities. This shift led to the development of multilayer PCBs, where multiple conductive layers were sandwiched together, enabling complex, high-performance designs.

Miniaturization and Flexible PCBs

As consumer electronics became smaller and more sophisticated, PCBs followed suit. Flexible PCBs, made from materials like polyimide, emerged, providing adaptability for devices with irregular shapes or those requiring bendable electronics. Miniaturization techniques like Micro-Electro-Mechanical Systems (MEMS) and Chip-on-Board (COB) further reduced the size of PCBs, enabling wearables and IoT devices.

Contemporary PCB Applications

Smartphones and Wearables

Smartphones exemplify the pinnacle of PCB miniaturization and complexity. They incorporate high-density interconnect (HDI) technology and employ numerous layers to accommodate advanced features like multi-camera systems, AI processors, and 5G connectivity. Similarly, wearables such as smartwatches and fitness trackers utilize flexible PCBs to conform to the human body.

Aerospace and Automotive

The aerospace and automotive industries rely heavily on ruggedized PCBs designed to withstand extreme conditions. In aerospace, PCBs are critical for avionics, navigation, and communication systems. In the automotive sector, PCBs power advanced driver-assistance systems (ADAS), electric vehicles (EVs), and infotainment systems.

Medical Devices and Healthcare

Innovations in medical devices, such as MRI machines, pacemakers, and remote patient monitoring systems, rely on PCBs for precise data acquisition and processing. Flexible PCBs are also used in wearable medical devices that continuously monitor vital signs.

Industrial Automation

Industrial automation systems, including robotics, factory machinery, and control systems, rely on PCBs for real-time monitoring and control. These PCBs are engineered for reliability and often feature redundant components.

Conclusion

The evolution of PCBs from their humble origins to their current state of sophistication has been nothing short of remarkable. As the electronics industry continues to advance, PCBs will play a central role in pushing the boundaries of what's possible. From consumer electronics to aerospace and healthcare, the impact of PCBs on our lives is undeniable, and their future promises even greater innovations and applications.